The Fastener Reinvented

Chances are you are using traditional helically-threaded fasteners and have been doing so for years. Now with Goldilocks™ ratchet fasteners you can:

with a fastener that does not need to be screwed together.

with a solution that in many cases fastens securely without tools.

with a sturdy fastener that is neither stretched nor torqued.

through powerful clamping forces that are free from vibrational slippage.

by using an innovative fastener that cannot screw loose.

with a solution that works as well in space and under water as it does on land.

with a system that is virtually tamper-proof.

resulting from loose fasteners that make things fall apart.

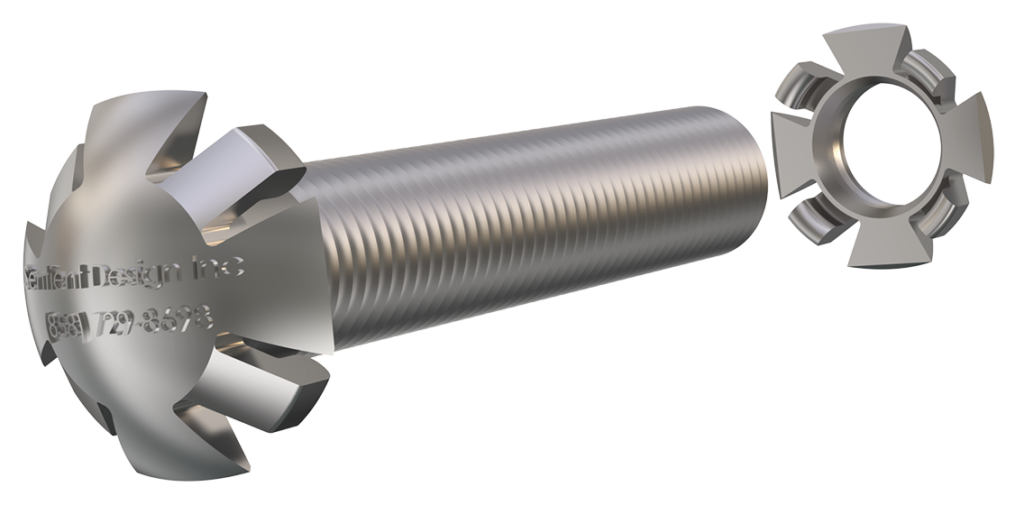

The Goldilocks™ fastener is an innovative, cost-effective solution that is easy to use and, once fastened, will not screw loose. It is a high holding force “push-to-fasten” (PTF) device that you can rely on forever.

Unlike traditional nut and bolt fasteners, it will not loosen over time and will stay fastened until you choose to remove and replace it. Owing to its integrated ratchet design, this new class of fastener was awarded multiple utility patents by the United States Patent and Trademark Office (USPTO).

A New Class of Fastener

Whatever your application, Goldilocks™ can decrease your cost, accelerate your manufacturing, and increase your reliability.

Fill out the form below for your FREE informational PDF!

About

Permanence When You Need It; Removability When You Want It

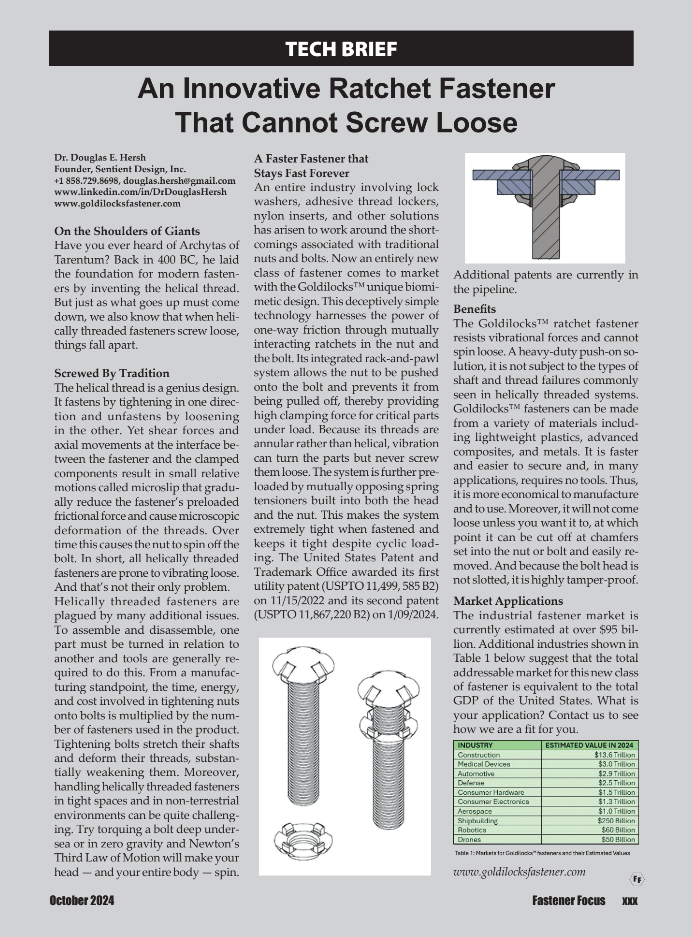

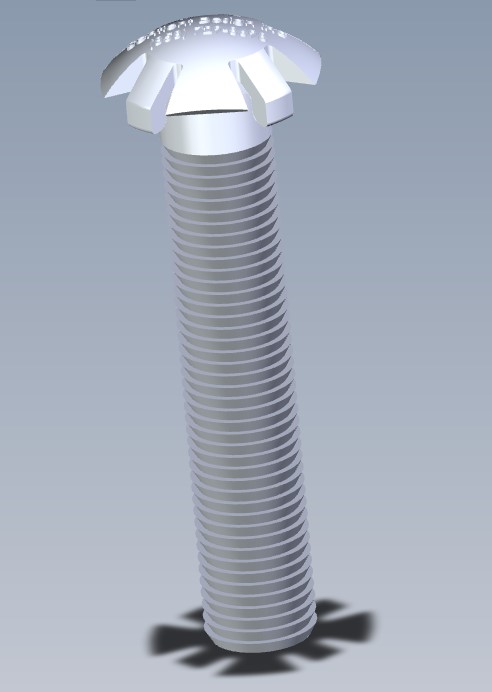

The Goldilocks™ unique biomimetic design offers an entirely new class of fastener for your high-strength application.

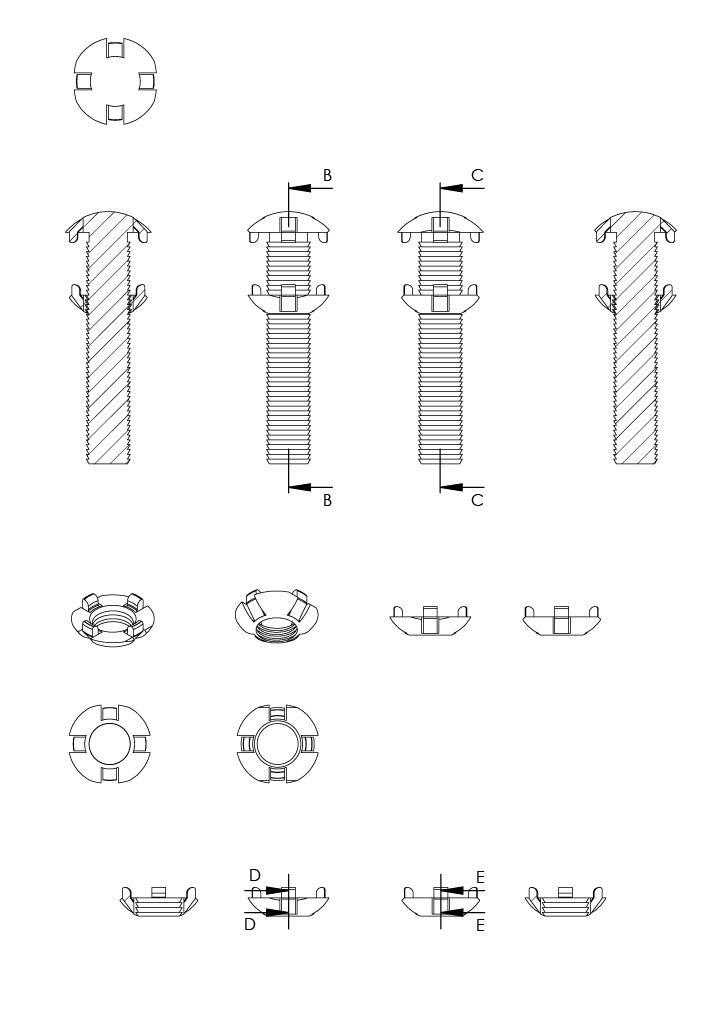

This deceptively simple technology harnesses the power of one-way friction through mutually interacting ratchets in the nut and the bolt. Its integrated rack-and-pawl system allows the nut to be pushed onto the bolt and prevents it from being pulled off , thereby providing high clamping force for critical parts under load. Because its threads are annular rather than helical, vibration can turn the parts but never screw them loose.

The system is further preloaded by mutually opposing spring tensioners built into both the head and the nut. This makes the system extremely tight when fastened and keeps it tight despite cyclic loading.

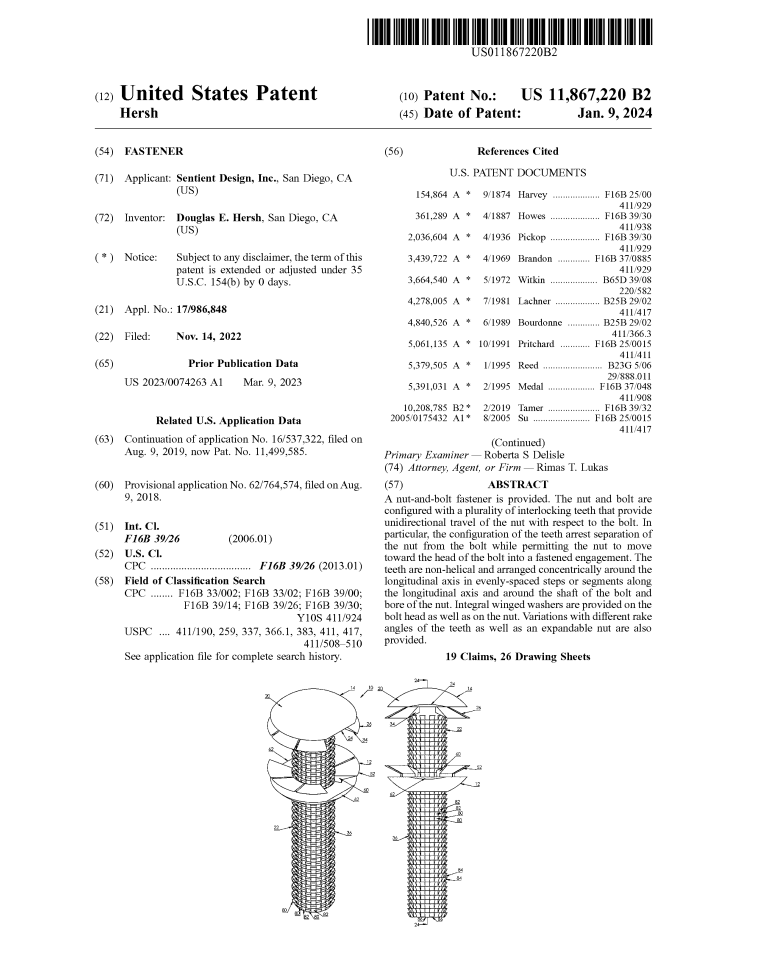

The United States Patent and Trademark Office awarded its first utility patent on 11/15/2022 and its second patent on 1/09/2024. Additional patents are in the pipeline.

Industries Served

You can use Goldilocks™ ratchet fasteners anywhere things are assembled for faster, more cost-effective, and more durable connections that will not screw loose. Goldilocks™ fasteners can be used to replace screws and nails as one-part fasteners or to replace nuts and bolts as two-part fasteners. Some the industrial applications include:

Aerospace:

Aerospace applications require precision and high-strength fasteners to hold aircraft components together. Whereas traditional aerospace fasteners often vibrate loose and have to be continually retorqued, transitioning to Goldilocks™ ratchet fasteners creates a tight connection that stays tight throughout the lifecycle of the aircraft.

Agriculture:

Reliable fasteners that can withstand environmental conditions are critical components for tractors, combines, and harvesters, in irrigation systems, pumps, and sprinklers, in grain silos, bins, and storage facilities, in livestock equipment, in greenhouses, and in an array of related farm equipment.

Automotive:

The automotive industry relies heavily on fasteners for assembling vehicles and their component parts. These components hold together various parts of cars, trucks, and motorcycles.

Construction:

Fasteners are widely used in construction to assemble structural components, secure building materials, and create sturdy connections.

Consumer Goods:

Everyday items like appliances, bicycles, and sporting equipment are assembled using a variety of fasteners to ensure durability and functionality. Now they can be built with Goldilocks™ ratchet fasteners to make them safer and more durable.

Electronics:

The electronics industry – – both consumer and industrial – – relies upon small, specialized fasteners to secure components on printed circuit boards and in electronic enclosures. Goldilocks™ ratchet fasteners are quicker and easier to use, resulting in enormous cost savings to the manufacturers of consumer and industrial electronics.

Furniture:

Furniture manufacturers use fasteners like screws, nuts, and bolts to assemble everything from chairs and tables to cabinets and shelves. Wherever these are used, Goldilocks™ ratchet fasteners are better and more reliable.

Heavy Equipment:

Many industries rely on heavy equipment that cannot afford to break down due to vibrational loosening of fasteners. Excavators, bulldozers, cranes, backhoes, loaders, graders, trenchers, compactors, pile drivers, tunnel boring machines and a host of additional equipment depend heavily on high strength fasteners that can withstand exposure to environmental and chemical factors.

Manufacturing:

Manufacturing processes across industries depend on fasteners to assemble products and machinery. This includes everything from consumer electronics to heavy machinery and equipment.

Medical Devices & Equipment:

Precision fasteners are crucial in the manufacturing of medical devices and equipment. They ensure the reliability and safety of these critical tools. Goldilocks™ ratchet fasteners can be made from non-toxic, non-reactive composites, plastics, and metals for safe and durable products and surgical interventions that do not fall apart.

Military and Defense:

The defense sector uses fasteners in the assembly of military vehicles, aircraft, and weapons systems. While fasteners often need to meet strict quality and security standards, rapid and cost-effective deployment of missiles, drones, robots, and other autonomous vehicles favor Goldilocks™ ratchet fasteners for one-and-done applications.

Oil & Gas Industry:

Durable fasteners are an absolute necessity in pipeline construction and maintenance, in drilling equipment, in refiners and processing plants, on offshore platforms, in subsea systems, in valves and pumps, in storage facilities, and in safety equipment and fire protection systems. In this industry, one loose bolt could lead to an extremely costly environmental disaster.

Rail Transit:

Reliable fasteners in the rail transit industry ensure the safety, durability, and functionality of trains, tracks, and related infrastructure such as rail cars, tracks, signaling and and electrical systems, catenaries, stations and platforms, rail bridges and other infrastructure. Here a failed fastener can quite literally lead to a train wreck.

Renewable Energy:

The energy sector uses fasteners in power plants, wind turbines, and solar panel installations. Fasteners must withstand extreme temperatures and conditions in these applications.

Robotics:

Fasteners are essential for maintaining the integrity, stability, and functionality of robotic systems. They are used in robot frame and body assembly, in motors and actuators, in sensor installation, in end-effectors, in printed circuit boards (PCBs) and electronic components, in articulation and joints, in housings and enclosures, in exoskeletons, throughout automated production lines, and in a great variety of related subsystems. A fastener that cannot spin loose can mean the difference between a robot with a long service cycle and a system that is down for costly repair.

Shipbuilding & Marine:

Fasteners in the marine industry need to be corrosion-resistant due to exposure to saltwater. They are used in boat construction, shipbuilding, and offshore installations.

Toys & Sporting Equipment:

Toys and sporting equipment take a beating and must stand up to repeated use under harsh conditions. Fasteners are used in rackets, clubs, helmets, and bats, and hold everything together from scooters to toy trucks. When fasteners come loose on toys and sporting equipment, accidents happen and people get hurt.